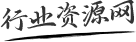

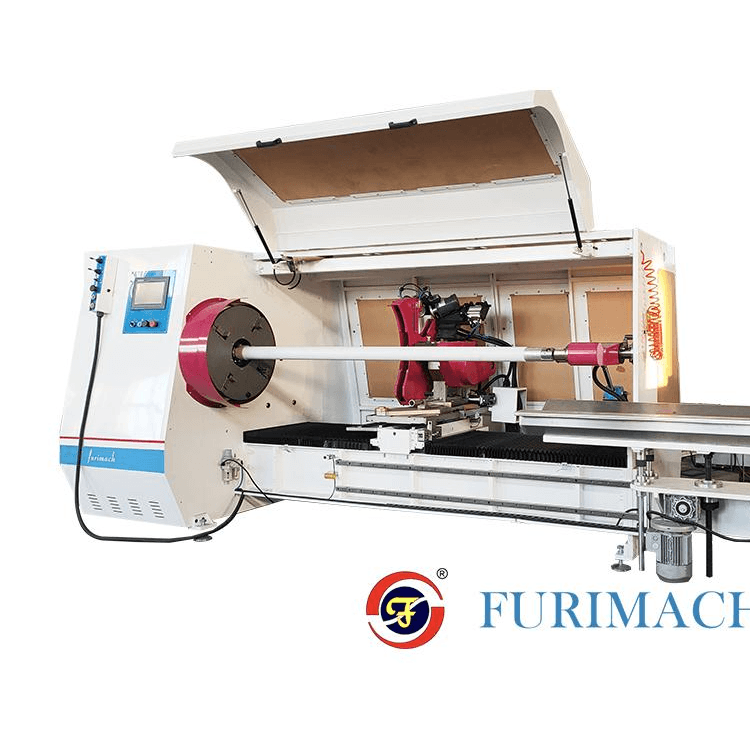

全自动装卸技术采用先进机械设计,软件系统,智能温控

实现了10个自动化:自动换卷,自动卸膜,自动装管,自动放气,自动充气,

自动上膜,自动回收,自动监测,自动补重,自动上料。

2组3轴换卷,不产生分条边料。

此技术可节约整机能耗3%以上。换卷卸料速度更快,对比单轴收卷,效率提高30%

设计线速:300m/min大收卷直径:φ350MM一人操作,

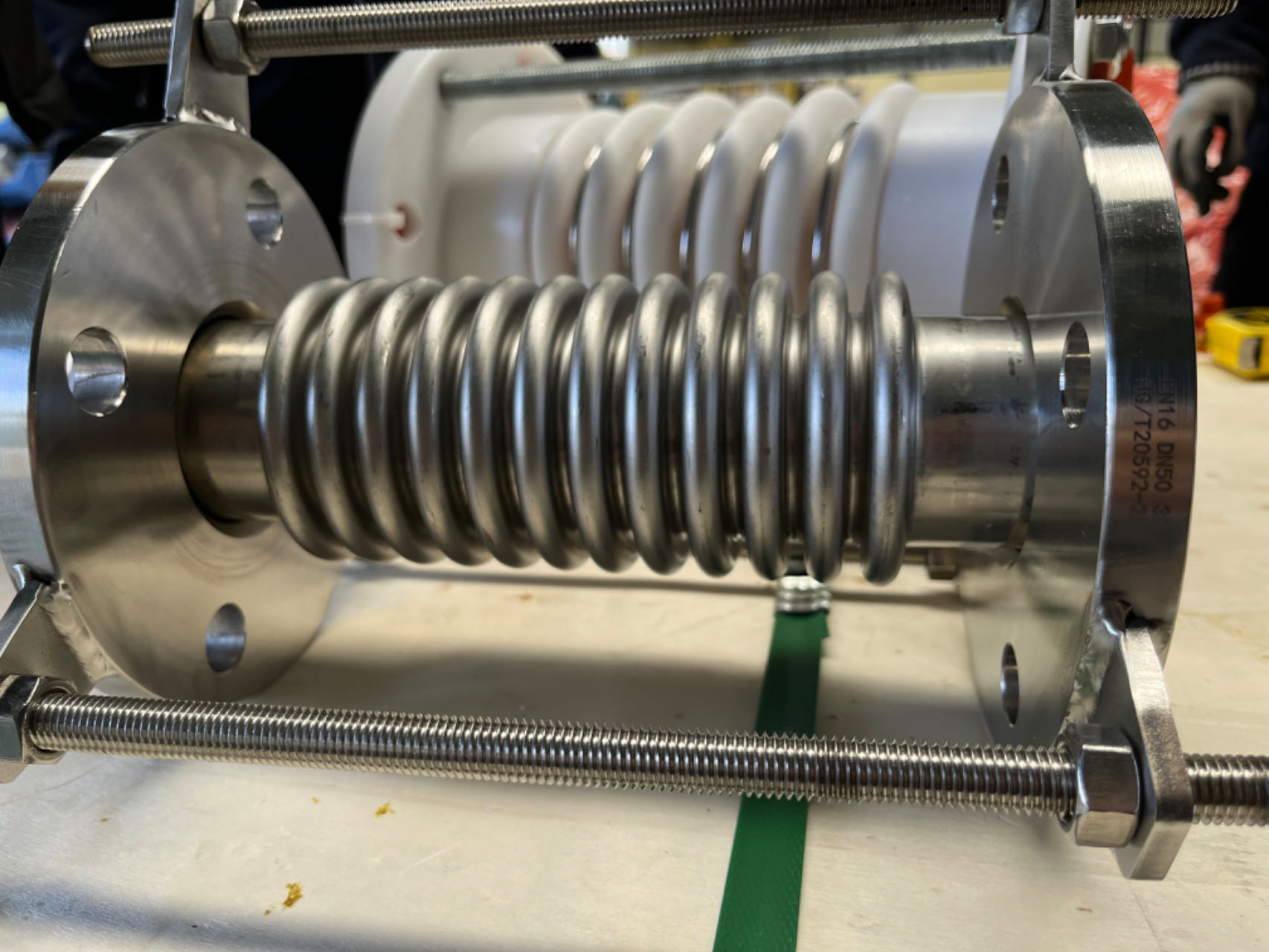

负压补偿技术:膜瞬间零间隙贴附在冷却辊上进行冷却成型,避免膜面缺陷。

高转速螺杆熔融技术:实现超高塑化,更高透明度

急速冷却定型技术(冷却辊表面温差≤±1℃,横向纵向拉伸力提高20%)。

Advanced mechanical design and software system for fully automatic loading & unloading. intelligent temperature control. 10 automatic actions fulfilled: auto roll exchange, auto roll unloading, auto core loading, auto deflation, auto inflation, auto roll lifting, auto film recycling, auto detection, auto weight compensation, auto roll loading.

2 sets of 3-shaft roll exchange, no slitting waste, which can save more than 3% of the overall machine energy consumption. Faster shaft exchange & unloading, the efficiency increases 30% compared to single shaft rewinding type. Designed line speed 300m/min, rewinding Max. Φ350mm. One person operation.

Negative pressure compensation technology: the film is instantly attached to the cooling roller with zero gap for cooling forming to avoid film surface defects.

High speed screw melting technology: to achieve ultra-high plasticization, super transparency.

Rapid cooling forming technology (cooling roller surface temperature difference ≤±1℃, transverse and longitudinal tensile force increased by 20%).

冀公网安备13010402003046号

冀公网安备13010402003046号