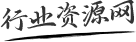

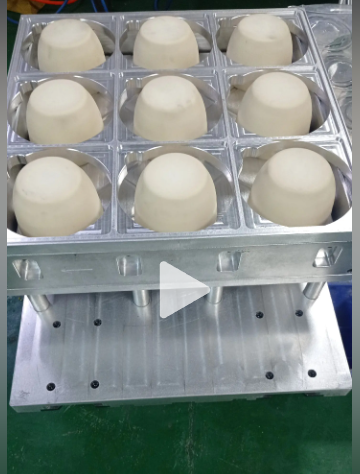

可生产淀粉植物纤维餐具,塑料餐具,碳酸钙塑料餐具,植物纤维碳酸钙餐具,可生产碗、杯、盘、快餐盒、便当盒,净菜盘等数百种产品,日产10﹣13万个快餐盒,30万个碗,全降解时间可任意控制。由于该产品属于一步法,颗粒原料加入后只经过螺杆一次加热成型,因此保持了塑料的塑性,省电。从挤出片材吸塑成型,连续不断、一气呵成,无需人工模切冲压,该设备也可用于生产聚乳酸餐具,碳酸钙、玉米淀粉聚乳酸餐具、脂肪族PBS淀粉生物塑料餐具。我司还替世界500强美国辛巴克咖啡生产耐热聚乳酸杯盖设备。该设备已出口台湾、韩国、印度、哈萨卡斯坦等地区。

只要更换模具便可生产,超市托盘、豆腐盒、冰淇淋杯、各种罐头盒、果脯盒、酱菜盒、糖果盒、巧克力盒、糕点盒、各种蔬菜、水果包装盒、蛋托、育秧盘、各种水产品速冻保鲜盒、、医疗器盒、玩具盒、小五金盒、文具、服装盒及其它各种日用品包装盒及各行业的包装产品。

Can produce starch plant fiber tableware, plastic tableware, calcium carbonate plastic tableware, plant fiber calcium carbonate tableware, can produce bowls, cups, plates, fast food boxes, lunch boxes, clean dishes and other hundreds of products, daily production of 10-130000 fast food boxes ,300000 bowls, the full degradation time can be arbitrarily controlled. Because the product belongs to one-step method, the particle raw material is added only after the screw is heated once, so the plastic plasticity is maintained and the electricity is saved. From the extrusion sheet plastic

molding, continuous, one-stop, no manual die-cutting stamping, the equipment can also be used to produce polylactic acid tableware, calcium carbonate, corn starch polylactic acid tableware, aliphatic PBS starch bioplastics tableware. We also produce heat-resistant polylactic acid cup cover equipment for the world's top 500 American Simbach coffee. The equipment has been exported to Taiwan, South Korea, India, Kazakhstan and other regions.

As long as the mold can be produced, supermarket tray, tofu box, ice cream cup, all kinds of can boxes, preserved fruit box, pickle box, candy box, chocolate box,f aquatic products frozen box, medicine box, medical device box, toy box, hardware box, stationery, clothing box and other daily necessities box and packaging products in various industries.

![]() 技术参数

技术参数

主螺杆 driving screw | 90mm | 工作速度 working speed | 30-35s/min | |

主螺杆长径比 Length-to-diameter ratio of main screw | 1:33 | 真空泵抽气速度Vacuum pump pumping speed | 70m3/h | |

螺杆转速 Screw speed | 10~80r/min | 极限真空度 final vacuum | 2×102Pa | |

加热系统 heating system | 65A | 气源压力 bleed pressure | 0.5~0.7mpa | |

挤出量 Extrusion | 100kg/h | 气源排量 Gas source displacement | 0.7~1m3/min | |

主电机功率 Main motor power | 22KW | 电源电压 supply voltage | 380V50HZ | |

吸塑成形功率 Power of suction molding | 1.5KW | 整机重量 Total weight | 6T | |

大成型面积 Maximum molding area | 800*300mm | 主引擎大小(毫米) Main Engine Size (mm) | ||

大成型深度 Maximum molding depth | 90mm |

![]() 特征描述

特征描述

挤出吸塑成型机技术参数

吸塑挤出机和成型机 采用的原料是塑料颗粒(碳酸钙)PP,边角料可回收重新生产。本套设备包括配机:真空泵,粉碎机,搅拌机,空压机, 全自动吸塑成型机。只要更换模头,可生产各种PP吸塑包装。 X-65 型整套价格:出厂价:130,000 RMB日产6万个快餐盒,15万个碗,盘。X-80型整套价格:出厂价:140,000RMB日产8万个快餐盒,20万个碗。X-90型整套价格:出厂价:150,000 RMB日产12万个快餐盒,28万个碗。X-65/80型价格:17万人民币整。日产13万个快餐盒,30万个碗。半自动的设备比全自动的设备出厂价少3万人民币。半自动80型出厂价:10.9万半自动90型出厂价:12万半自动65/80型出厂价:14万

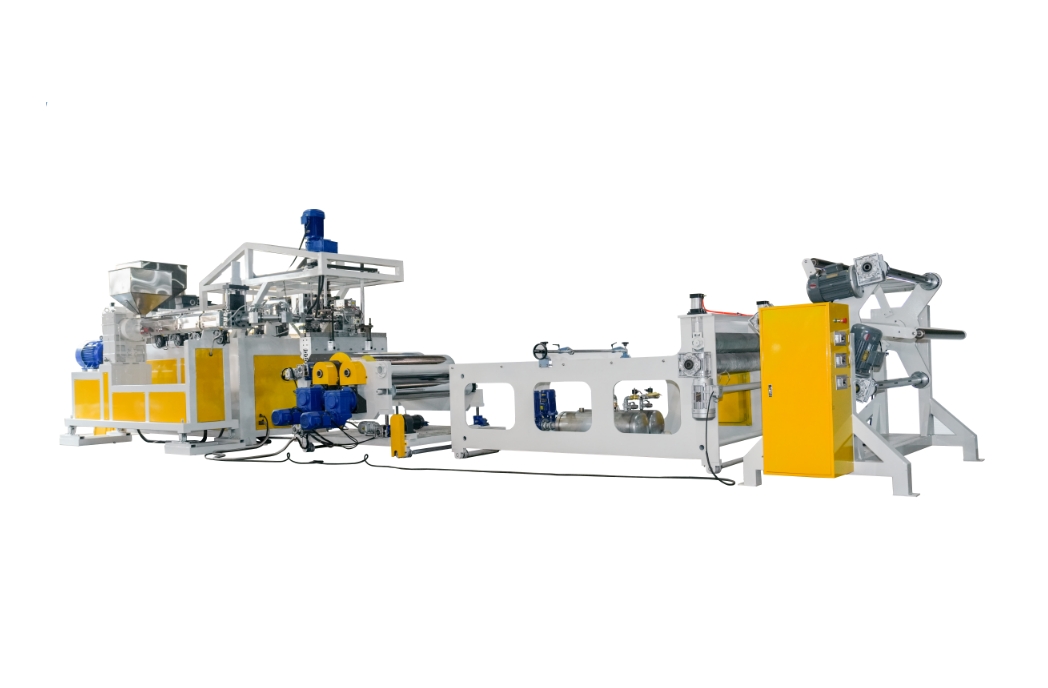

单层挤出机

Single layer extruder

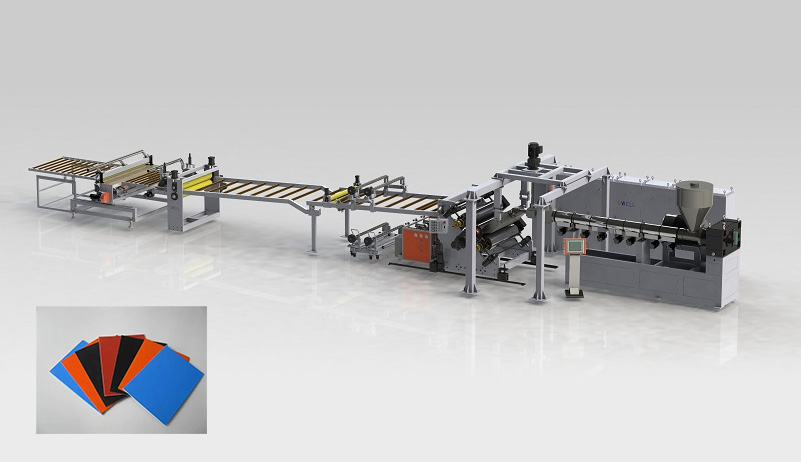

三层挤出机

Three-layer extruder

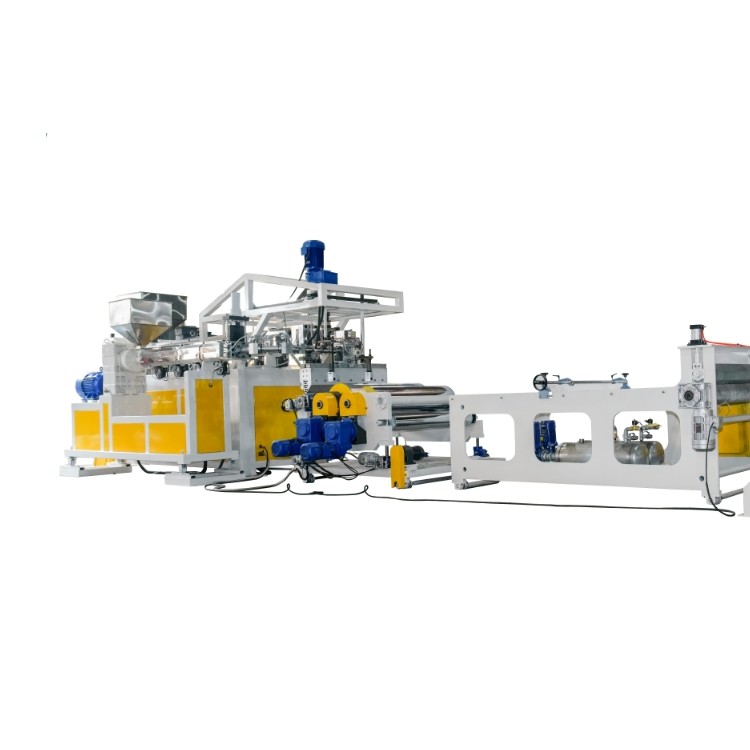

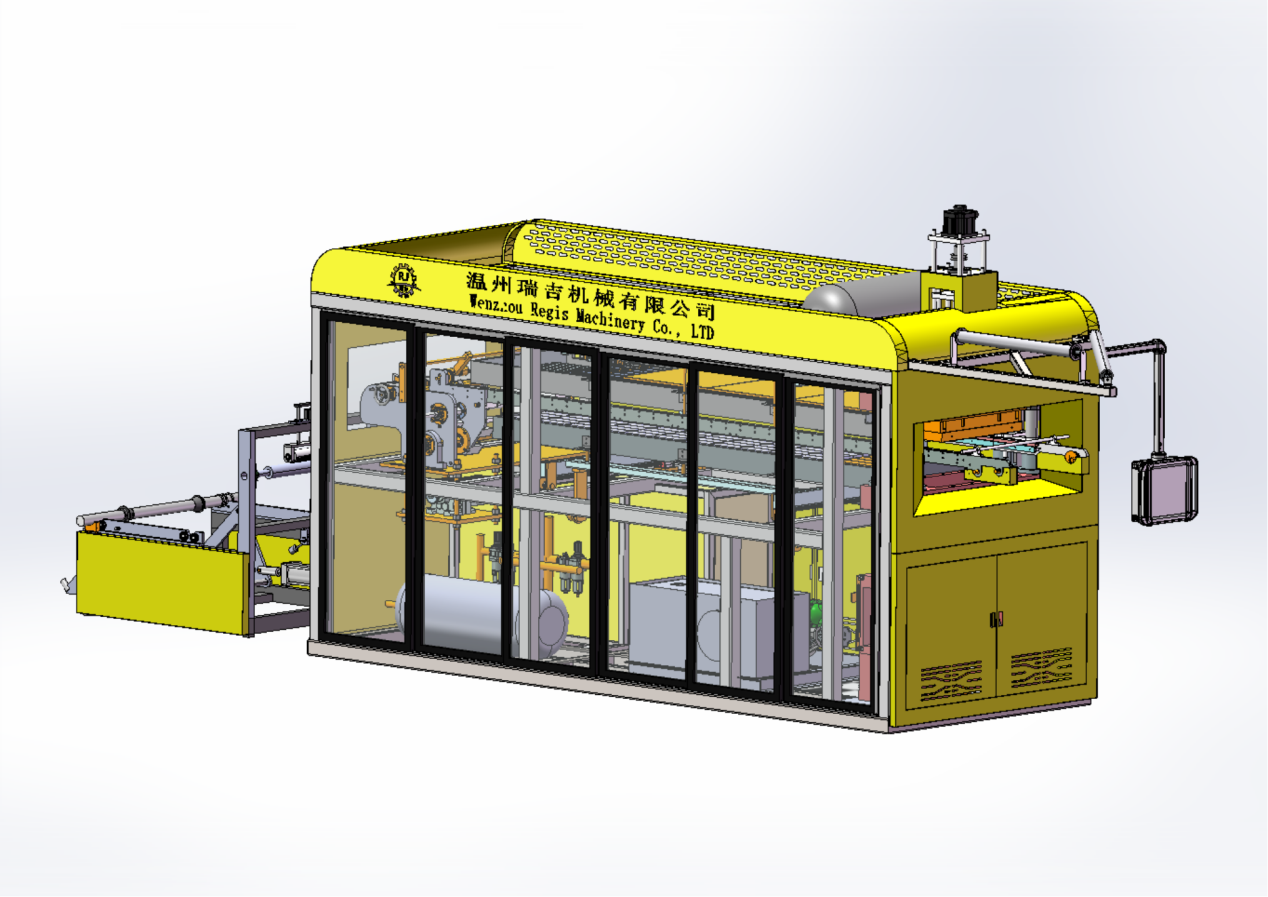

成型机

forming machine

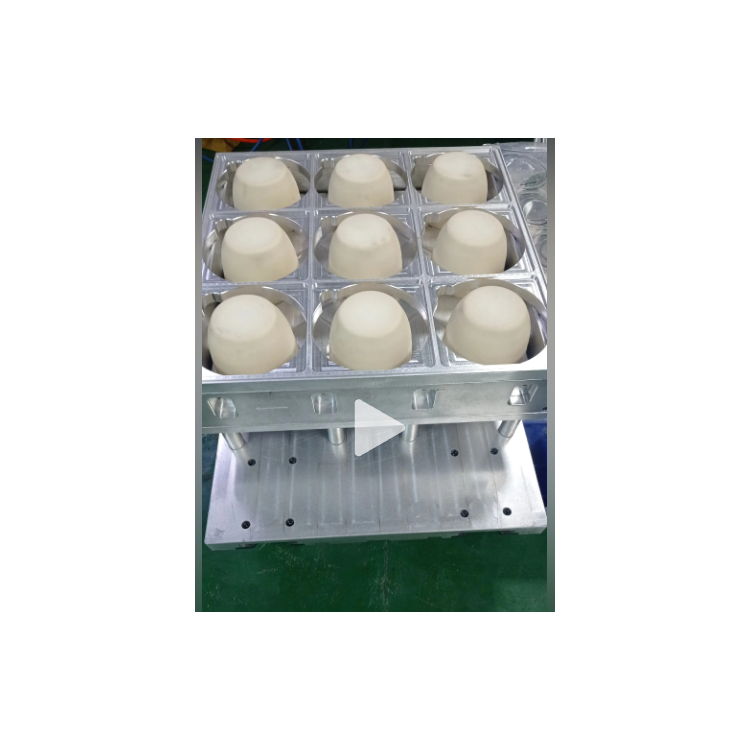

推送机

Push machine

合作商

冀公网安备13010402003046号

冀公网安备13010402003046号