产品描述

· 应用原理 (Application principle):

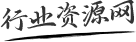

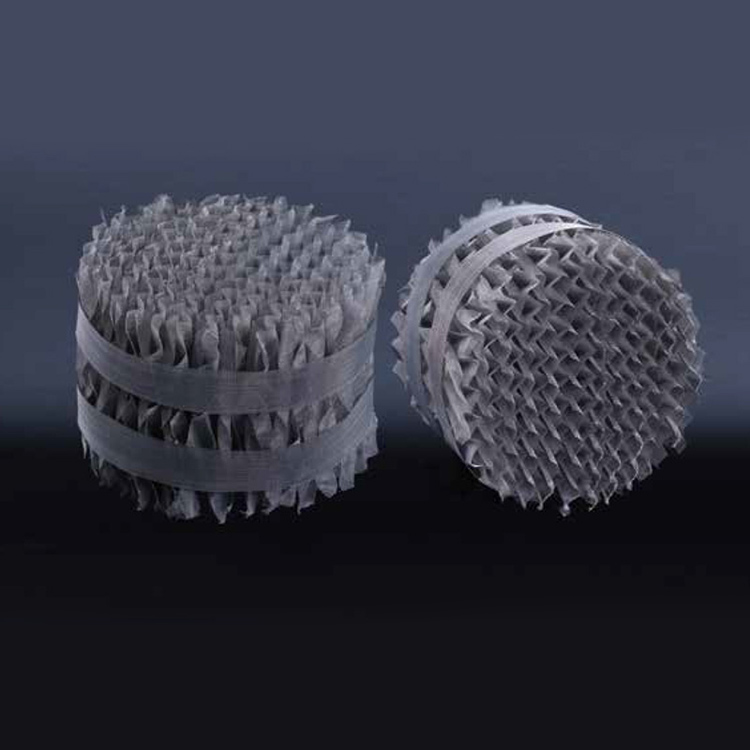

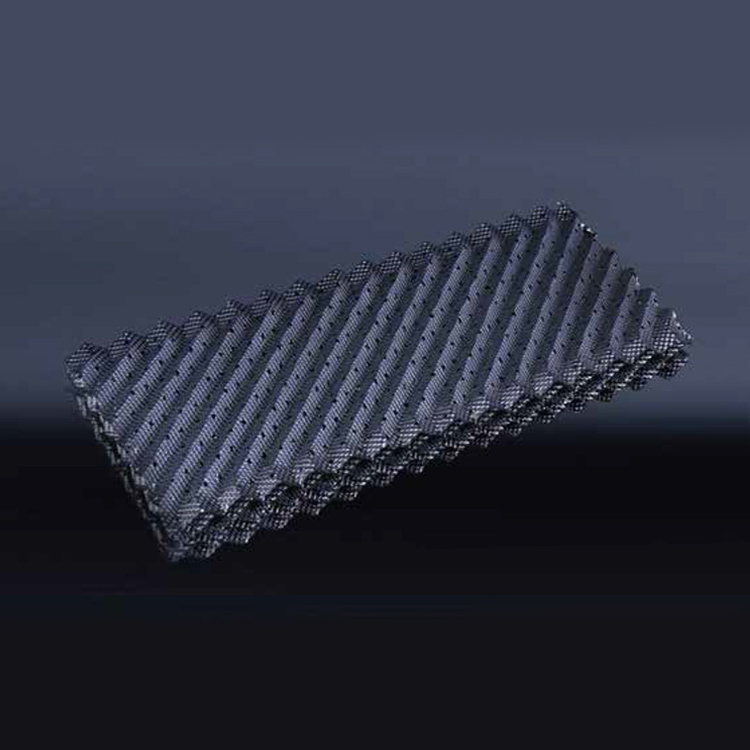

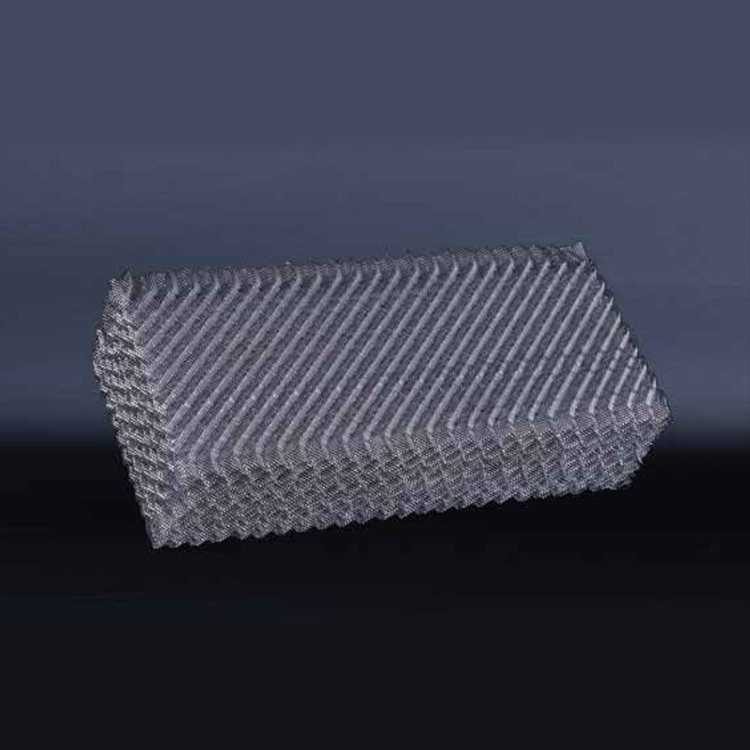

陶瓷波纹填料是一种新型规整填料,它是由许多具有相同几何形状的填料单元体组成。由于陶瓷独特的结构,具有良好的亲水性能,其表面可形成极薄的液膜的湍动及气流的倾斜曲折通道能促进气流但又不阻挡气流使陶瓷填料能与金属填料相匹敌,而其耐腐蚀、耐高温性能金属填料却无法相比。表面结构有良好的湿润性能,能使液体加快流动、使填料滞液量降至低。从而降低了过热、聚合和结焦的机会。

Ceramic corrugated packing is a new type of structured packing that consists of many packing units with the same geometry. Due to the unique structure of ceramics and good hydrophilic properties, the surface can form a very thin liquid film turbulence and the oblique zigzag channel of the gas flow can promote the gas flow without blocking the gas flow so that the ceramic packing can compete with the metal packing. Its corrosion-resistant and high-temperature resistant metal packing cannot be compared. The surface structure has good wetting properties, which can make the liquid flow faster and minimize the liquid retention of the packing. This reduces the chance of overheating, polymerization and coking.

· 物理性能 Physical properties:

| 指标 Index | 比重 Density | 吸水率 Water absorp-tion rate | 耐酸性 Acid resis-tance | 耐碱性 Alkali resis-tance | 破碎强度 Breaking strength | 莫氏硬 Mohs hard | zui大操作温度化 Maximum operating tempera-ture |

| 数值 Num-bers | 2.4 g/cm3 | ≤5% | ≥98% | ≥86% | ≥130Mpa | ≥7 | 800℃ |

· 技术参数 Technical parameter:

| 型号 Type | 比表面积 Surfacearea ㎡/m3 | 堆比重 Density kg/ m3 | 空隙率 Void rate % | 倾斜角 Inclined angle | 压力降 Pressure drop mmHg/m | 理论板数 Theory sheet no. m-1 | 水力直径 Hydraulic Dia. mm | 液体负荷 Liquid load m3/m2h | F因子 F factor m/s(Kg/m3)0.5 |

| 125Y | 125 | 320 | 90 | 45° | 1.8 | 1.8 | 28 | 0.2-100 | 3.0 |

| 160Y | 160 | 370 | 85 | 45° | 2 | 2 | 15 | 0.2-100 | 2.8 |

| 250Y | 250 | 420 | 80 | 45° | 2 | 2.5 | 12 | 0.2-100 | 2.6 |

| 350Y | 350 | 470 | 78 | 45° | 2.5 | 2.8 | 10 | 0.2-100 | 2.5 |

| 400Y | 400 | 500 | 75 | 45° | 3 | 3 | 7 | 0.2-100 | 2.0 |

| 450Y | 450 | 520 | 72 | 45° | 4 | 4 | 2.2 | 0.2-100 | 1.8 |

| 550Y | 550 | 620 | 74 | 45° | 5.5 | 5-6 | 6 | 0.18-100 | 1.4 |

| 700Y | 700 | 650 | 72 | 45° | 6 | 7 | 5 | 0.15-100 | 1.3 |

冀公网安备13010402003046号

冀公网安备13010402003046号